Faster than a bullet

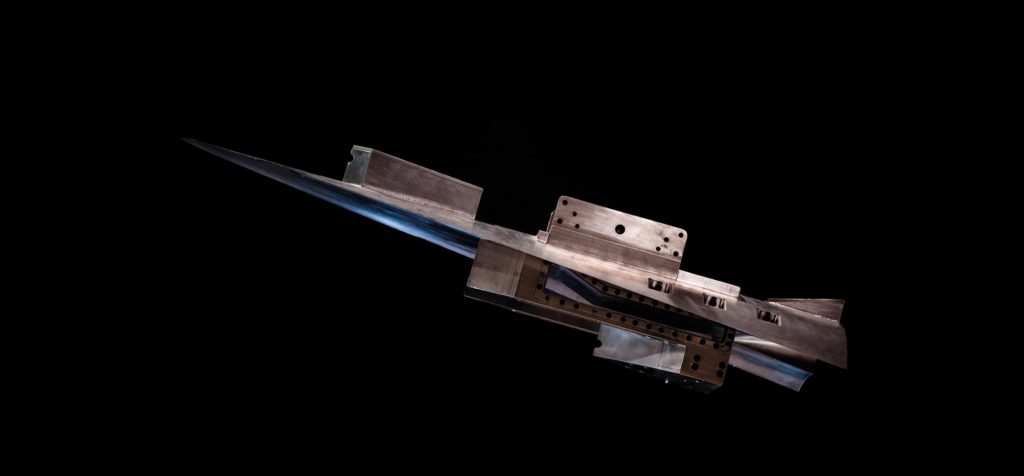

Van laboratory model – Léo Ramos Chaves

If everything goes as planned, the Brazilian Air Force (FAB) will carry out flight testing of the first hypersonic aeronautical engine made in the country within two years. The test is part of a broader project whose objective is to master the development cycle of hypersonic vehicles, which fly at least five times the speed of sound, or Mach 5. Mach is a unit of measurement of speed corresponding to around 1,200 kilometers per hour (km/h). The program is coordinated by the Institute of Advanced Studies (IEAv), one of the research centers of the FAB’s Department of Aerospace Science and Technology (DCTA), in partnership with the company Orbital Engenharia, both from São José dos Campos (SP).

In addition to the hypersonic engine, the 14-X Hypersonic Propulsion (PropHiper) project, started in 2006, envisages the construction of an unmanned aerial vehicle (vant), where the engine will be installed. Named 14-X, in honor of the 14-Bis, the vant will employ the concept of a waverider, in which a shock wave generated below it, due to its high speed, provides it with lift. It is as if, during the flight, the vehicle “surfed” on the wave induced by it.

UAV 14-X

Length 4 m

Wingspan 1.2 m

Weight about 750 kg

Speed 12,000 km/h

Flight altitude 30,000m to 40,000m

“There are still no hypersonic aircraft in routine operation in the world. This technology symbolizes the state of the art even for countries like the United States, Russia and China”, informs Colonel Lester de Abreu Faria, electronic engineer and director of IEAv. “Everyone seeks this knowledge and, despite the long development time, we are not far behind the world leaders.”

According to Israel Rêgo, manager of the PropHiper project, the hypersonic engine under development in the country, of the scramjet (supersonic combustion ramjet) type, can also be used as a second or third stage of rocket propulsion – these space vehicles are equipped with several stages (or engines), activated successively throughout the flight. In the first test, scheduled for 2020, the scramjet engine will be installed in a sounding rocket at the Institute of Aeronautics and Space (IAE), a DCTA unit focused on developing technologies for the aerospace sector. The project was supported by FAPESP.

Scramjet engine test in wind tunnel – Léo Ramos Chaves

The hypersonic aerial vehicle integrated with the scramjet engine can be used as a passenger plane or for military purposes. In 2018, Russia and China successfully tested the Avangard and Xingkong-2 hypersonic missiles, respectively. In the United States, Lockheed Martin is building a hypersonic vehicle for flight at Mach 6.

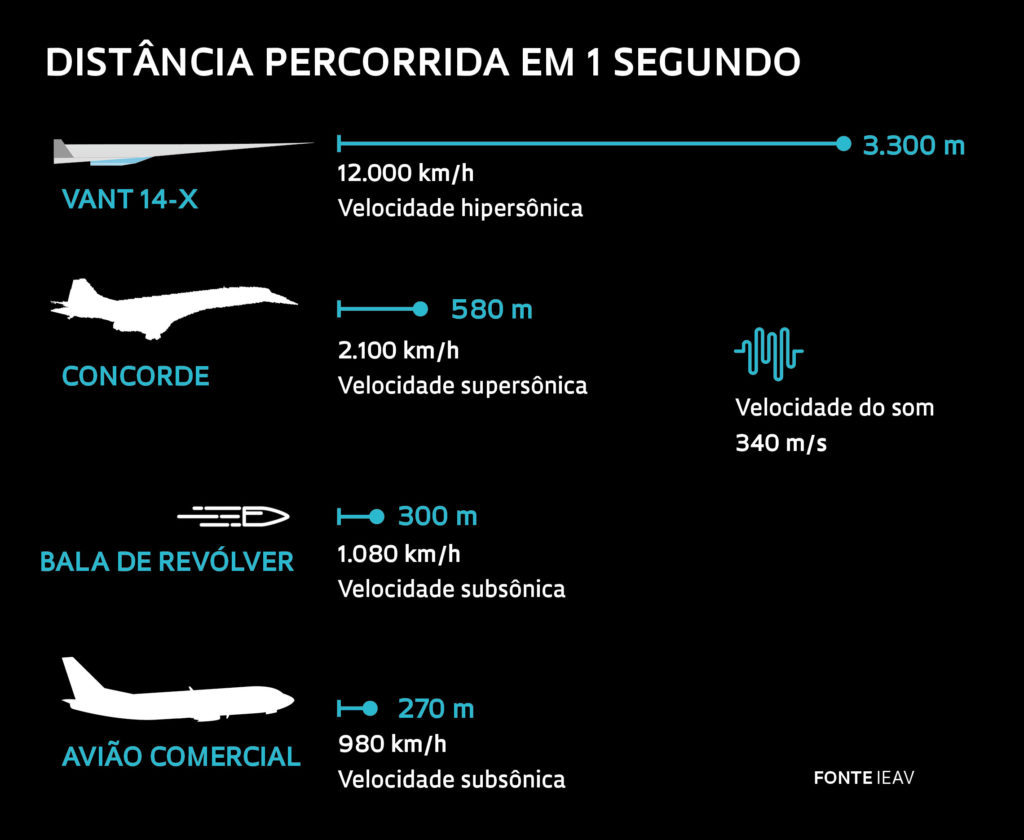

Since the beginning of the project, R$53 million has already been invested in the 14-X, programmed to fly at Mach 10 (12 thousand km/h) (see infographic). “Half of the program’s time was dedicated to training staff and implementing laboratory infrastructure, with emphasis on the T3 hypersonic shock tunnel where aerodynamic tests are carried out [see Pesquisa FAPESP no 135]”, says Rêgo. “The big leap now is to ‘leave’ the laboratory and operationalize the waverider and engine technologies in flight.”

Some challenges, however, still need to be overcome. The first is the completion of the scramjet. Like commercial jet engines, the scramjet uses air from the atmosphere to burn fuel. However, unlike aircraft engines, the 14-X has no moving parts such as compressors and turbines. “In supersonic combustion, the captured air must be decelerated, pressurized and heated before entering the combustion chamber, where the fuel is injected. And this depends on the perfect geometry of the engine”, says Rêgo.

Another difficulty with the project is making the vehicle resist the friction generated by flying at hypersonic speed. “The parts that undergo greater heating due to friction with the air must be made of materials resistant to high temperatures, while the coldest must be made of aeronautical steel or aluminum”, explains Colonel Marco Antônio Sala Minucci, aeronautical engineer and hypersonics consultant at the project 14-X.

Finally, it is necessary to make perfect integration between the engine and the hypersonic vehicle, since the drag (force against displacement) in hypersonic flight is very high. “The front part of the vehicle must function as an air intake [in the engine], producing compression, while the rear part must operate as a nozzle, transforming the high temperature and pressure of the supersonic combustion chamber into thrust. Thus, the engine and the vehicle become indistinguishable, reaching extremely high flight speeds”, says Israel Rêgo.

Source: FAPESP – https://revistapesquisa.fapesp.br/mais-rapido-do-que-uma-bala/